To keep your pruning shear blade sharp, follow INFACO's sharpening advice. This way, you're guaranteed to optimise your blades and get clean cuts.

Thanks to the INFACO electric sharpener, you can sharpen your blades in record time and easily maintain a penetrating blade profile. With an electric sharpener, you can save a considerable amount of time on daily sharpening, optimise your blades to the maximum and get more out of your pruning shears!

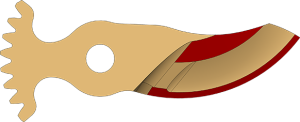

Sharpening must be carried out flat, on both red slants, to maintain the same penetration angle at all times.

The INFACO electric sharpener is compatible with F3005 / F3010 / F3015 / F3020 batteries. If you'd like to buy one, contact your usual distributor.

Using the INFACO tungsten carbide sharpener keeps the blade sharp. A sharp blade guarantees impeccable cutting quality and reduces the risk of any wood diseases spreading.

The sharpener should be used four times on the bevel and once on the counter-bevel (back of the blade). Sharpening alone is not enough; it must be done in addition to sharpening.

To sharpen your pruning shears properly, INFACO advises you :

To optimise blade life as much as possible, while maintaining perfect cutting quality, daily blade maintenance is essential. It also helps to :

On the other hand, poor blade penetration leads to a significant reduction in cutting capacity, requiring several pulses for medium cuts, higher power consumption, reduced battery life, faster blade wear, overheating of the motor, loss of time and profitability and greater strain on the pruner's wrist.

To maintain your pruning shears properly, INFACO recommends other essential care measures such as greasing the shear blade at least twice a day, tightening the blade properly, changing the blade if necessary, cleaning the cutting head and carrying out annual maintenance. Visit our videos section to view all the demonstration tutorials.