For over 40 years, INFACO has been designing and manufacturing its famous professional electric pruning shears in France. Behind each product lies a subtle balance: preserving traditional know-how, while structuring production through clear procedures and work instructions. This is what enables INFACO to guarantee consistent quality, remain true to its Origine France Garantie (OFG) commitment and continue to innovate.

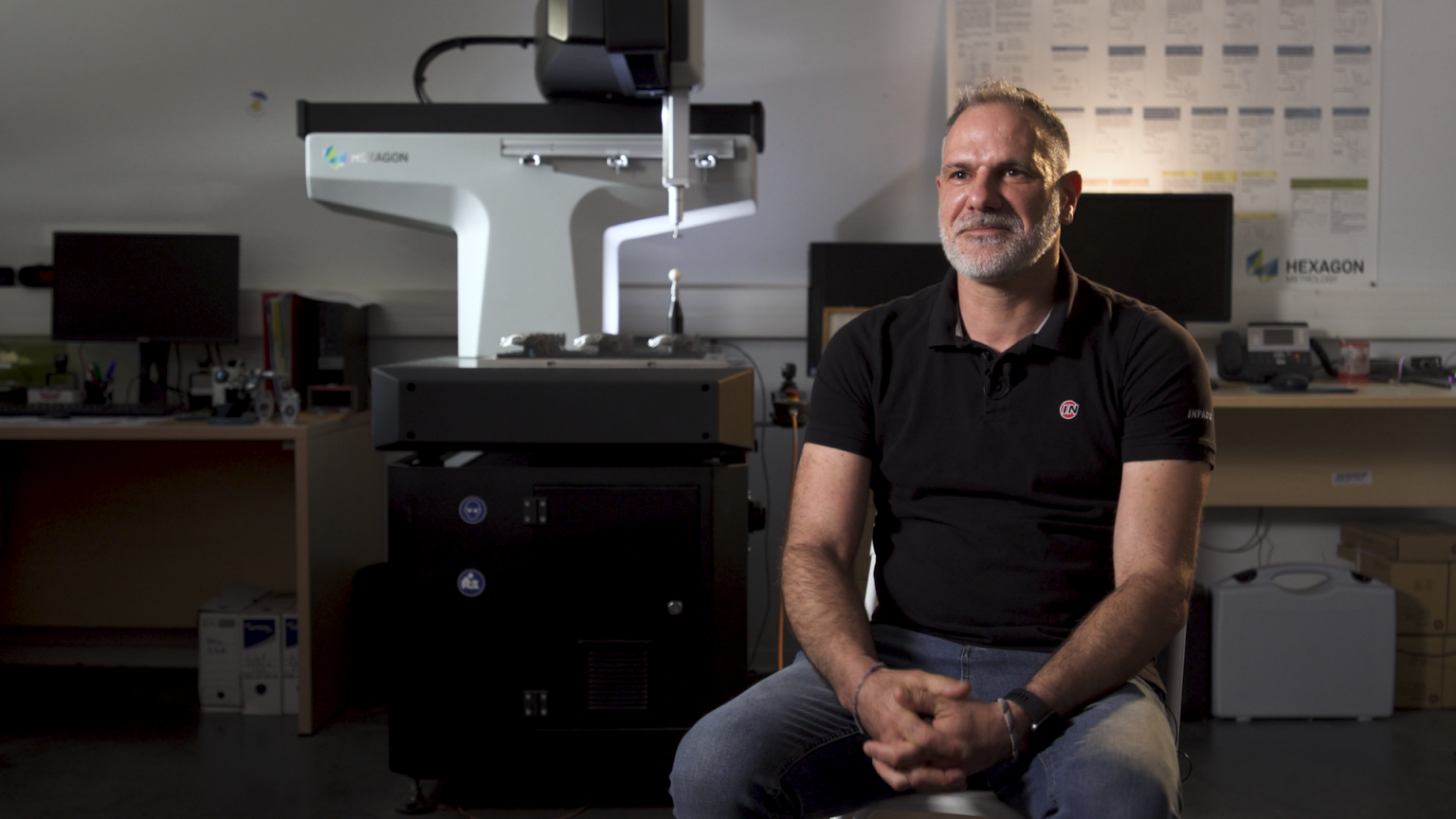

When Greg Alvarez joined INFACO in 1999, the company had just twenty employees. At the time, everything depended on the passion and know-how of the people who worked there. Daniel Delmas, the company's founder, embodied this creative energy: he knew how to do everything, he passed on his knowledge, but nothing was yet formalised. Very quickly, Greg and his colleagues realised thatthey had to capitalise on this know-how and put in place procedures and work instructions to ensure that every machine left the workshop with the same quality, with no deviations. These processes are also used to integrate new employees and provide a secure training environment.

In 2014, INFACO was awarded the OFG label. This demanding distinction requires that more than 50% of the cost price of the tool comes from France. Every year, an audit verifies the accounts, the product nomenclature, the workforce... An intrusive but necessary process, which guarantees transparency and traceability. Maintaining this label while offering premium machines like the pruning shears requires daily rigour. And all of this without driving up the price, including VAT, for the end user.

Quality at INFACO is not just a word: it's a living process. Service and overhaul statistics enable us to monitor the reliability of our machines, and to detect any recurring breakdowns, broken parts or conditions of use (whether in vineyards, arboriculture or green spaces). This data is passed on to the design office and incorporated into the design phase for each new tool, thanks to what is known as 'feedback from experience'.

From 25 employees in 1999 to over 110 today, INFACO has grown without losing its soul. For Greg, the key is simple: never rest on your laurels. Always moving forward, improving, innovating, while cultivating the goodwill and loyalty that have always characterised the company. It is this unique combination that enables INFACO to remain the world leader in professional electric pruning shears, with products designed to last and thought out for users.

Look out for episode 8 of our special 40th anniversary series very soon, with an interview with Christophe Gout on Research and Development! To celebrate our anniversary, the company's key figures look back at its history, from the very first Electrocoup to flagship models such as the F3010, F3015 and F3020.

It's called "INFACO, the series" and it's broadcast all year round on our website and social networks in 11 episodes!

👉 Subscribe to our newsletter for exclusive content!

It was Daniel Delmas, founder of the company INFACO, who invented in 1984 the world’s very first electric pruning shear: the Electrocoup. Since then, INFACO has never stopped innovating, whether with iconic models such as the F3015 and the F3020, or with technological advances like increasingly efficient lithium batteries.

Buying a professional electric pruning shear made in France guarantees reliable equipment, consistent cutting quality, responsive after-sales service, and good availability of spare parts and accessories. It is also a choice that supports local jobs, sustainability, and long-term performance.

The F3020 battery-powered pruning shear and the Electroliv olive shaker are OFG certified. They are manufactured in Cahuzac-sur-Vère, with a large portion of the components (such as the blade) produced in France. These models meet the needs of professionals seeking reliability and user comfort.

Even if not all of our tools are certified, they are designed with the same commitment to local manufacturing, giving preference as much as possible to French suppliers and expertise.

Choosing equipment made in France means supporting the local economy while investing in a product designed to reduce effort, make daily work easier, and ensure autonomy suited to the needs of the field.

All INFACO equipment is available through our network of authorized stores and distributors worldwide. You can test it, ask questions about maximum cutting diameter, blade openings, handling, battery life, or charger performance.